Services /

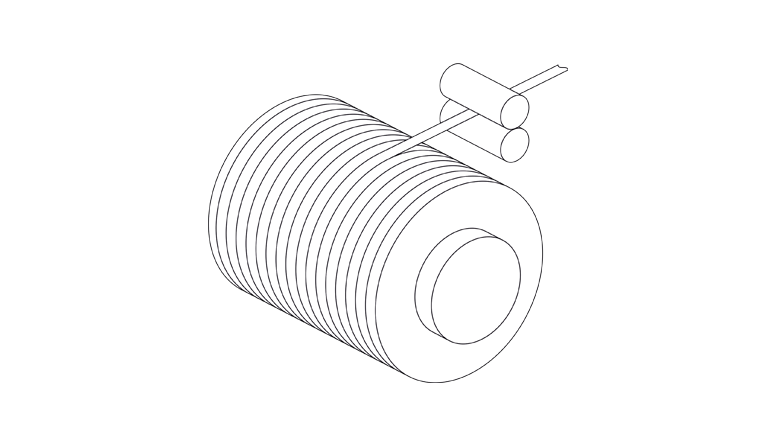

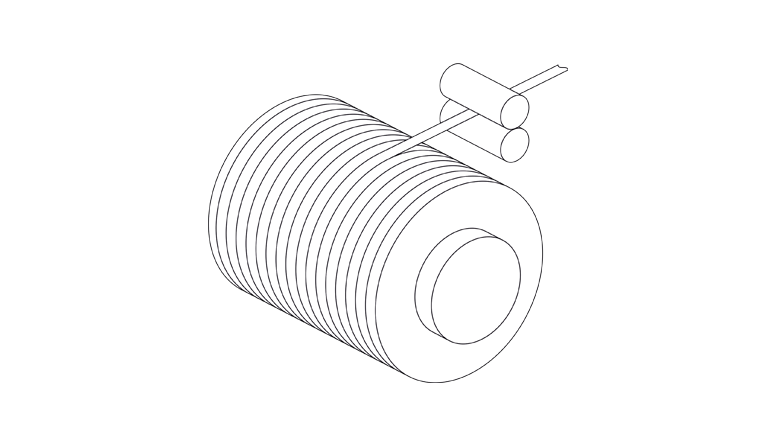

Spooling

Services /

Are you looking for a solution to improve the production process using tapes? Do you want to reduce production downtime associated with changing rollers of traditional lengths?

In our offer, you will find spooled tapes with lengths of even tens of thousands of meters. This will extend the working time of machines without the need to stop the production process.

During the spooling process, we maintain constant quality control, ensuring that the tapes on spools purchased from our company are of high quality. We wind the tape of your choice on the spool, suitable for the production processes in your facility.

Spooled tapes for a wide range of industries:

Spooled tapes for the automotive industry - for the production of car trims, decorative strips, or assembly applications.

Spooled tapes for construction - for the production of window expansion strips, glazing, decorative window muntins, and for assembly.

Spooled tapes for the advertising industry - for the production of price tags, decorative strips, or POS materials.

Spooled tapes for the packaging industry - for the production of packages such as envelopes with adhesive strips or siliconized paper.

Spooled tapes for the furniture industry - for the production of wardrobe brushes or blinds.

What will you gain by using spooled tapes in production processes?

The use of tapes on spools significantly extends the working time of machines without the need to stop production for roller replacement. Implementing production with spooled tapes works excellently on extruder-type devices used, for example, in the production of building profiles, price tags, etc. Having more material on a spool accelerates production and reduces costs associated with stopping the production line.

Using tapes on spools not only extends the machine's working time but also eliminates the need for frequent roller replacements and ensures correct and efficient tape application. Extending the tape winding through the spool also optimizes resource utilization, significantly reducing the amount of unused waste and shortening the working time of employees while ensuring greater certainty of correct tape application.

Individual approach to customer needs:

The length and width of the supplied tapes are tailored to the customer's production processes. Spools can reach non-standard lengths (even up to tens of thousands of meters), and their minimum width is 4mm. Here, you will find adhesive tapes whose width can be strictly tailored to your company's needs. Furthermore, tapes can be wound on spools, allowing you to obtain a product with a larger winding, the length of which is also customized to meet customer expectations.

You can order spools starting from just 9 pieces. This low minimum order quantity (MOQ) sets us apart from the competition. This way, you can test the application of spools in your own production processes.

Discover our technology for manufacturing tapes on spools:

We produce spools using the traditional cross-winding method, which allows us to create tapes tailored to the customer's machine park requirements, significantly influencing the efficiency of the production process.

During the spooling process, we wind hundreds or even thousands of meters of adhesive tape on one spool. The length of the wound tape depends on its width, type, and adhesive used.

We typically produce spools without additional interleaving, but for materials with high adhesiveness, we use additional protective interleaving to prevent the material from sticking together on the spool.

Our advantage is a modern machine park capable of preparing tapes on spools that meet customer expectations. The professional machines we use significantly reduce the number of connections on one spool.